Diamond Grille Security Doors plus Flyscreens

$340.95 – $540.95

Premium quality Diamond Grille security doors with different types of flyscreen mesh.

Diamond Grille Security Door

Premium quality diamond grille security door with different types of flyscreen mesh. The combination of flyscreens includes fibreglass, pet mesh, stainless steel and one-way mesh to protect fly coming in the house.

It is simple as you select from three different size ranges, small, medium and large to fulfil your need, which covers 99% of Australian doors, and if yours is not in the standard size range list, there is always a space for customisation.

Premium 20mm thick frame with all different colours gives you real security and preferences.

Features of various flyscreen meshes:

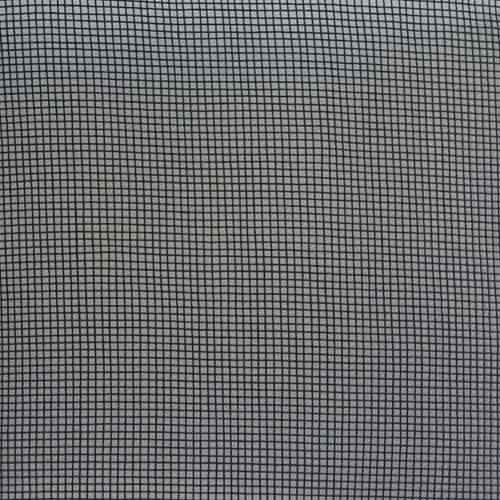

Fibreglass:

Economical, adaptable and simple to install. It won’t wrinkle or disentangle. It is also versatile and durable. Withstands in most atmospheres such as salt air, mechanical exhaust and so on. It is the most basic screen mesh for construction.

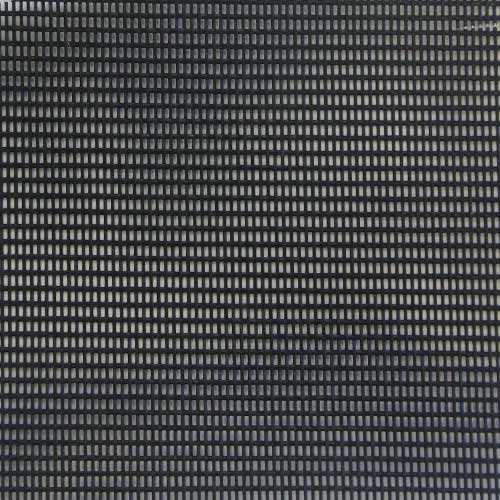

Pet mesh:

Thick nylon mesh with matt black finish is a serious barrier against fly or pet scratches. It is intended to confront the manhandle of most cats and dogs. If you have vigorous pets that are harming your standard fibreglass screen in your entryways, then this pet mesh screen is your option. .

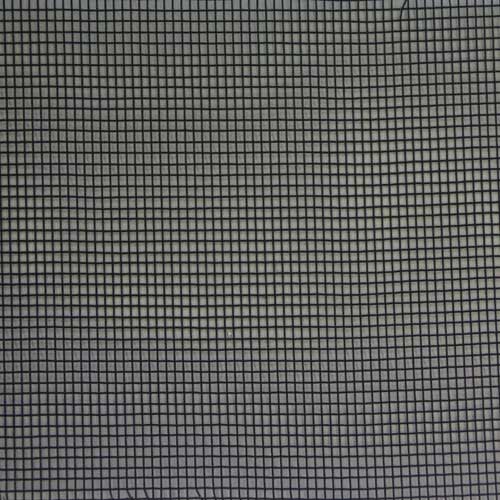

Soft stainless steel mesh:

Superior quality and durability for additional security against flame and erosion. Therefoer, it is best utilized for beachfront zones and highlights Diamond Grille Security Door with fire rating. It has met the Australia Standard AS3959-2009: Development of Working in Bushfire-inclined Ranges.

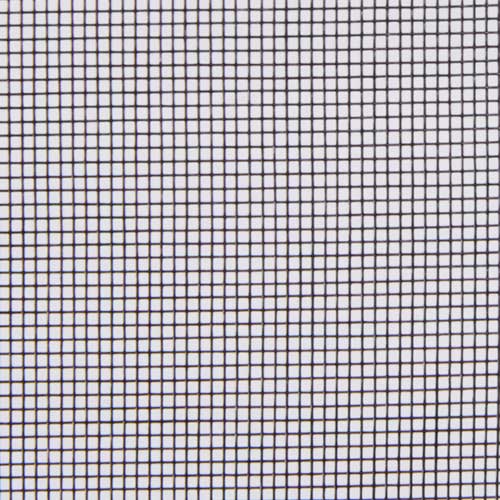

One way mesh:

Aluminum punctured work for screen entryways that is intended to make the impact of having the capacity to see through from one side to the next without the opposite side having the capacity to see back. Thus, the production of one-way vision. It gives you the premium add-on feature for your home security door.

1. Hinged Door Measurement

MEASURE POINTS

ALLOWANCE CHECK

READ OFF A BENT TAPE

To read off a bent tape, we generally recommend reading it just before the bend, as shown in the photo below. The tip is to place the bend against the corner as tightly as possible. If you place the bend at the corner and you read the number right before the bend, you can add 1~2 mm to the read, and that would be your measured opening. In this case, 301mm is pretty accurate. Measure twice or three times until you get the same number. 1 or 2mm off will not really impact the installation of the screens as there are many ways to pack or chisel the opening to make it fit.

MEASURING WITH THE TAPE LENGTH

Alternatively, you can place the tape measure inside the opening and include the tape body as part of the measurement. You need to add the tape body length to the measurement to get the final read. Most of the tape will have its own body length indicated on the case, else you can measure the body length first.

METHOD

1. Measuring for a new screen door, build from scratch:

Door Height: Measure from top (1.1) to bottom (1.2) on both sides of your door frame, and record the shortest measurement.

For all PRODUCT BUILDERS, if you choose the build “from scratch” option, please enter the number in the text field named opening height. The new door height will be automatically generated based on the measurement you entered.

For the fast track ordering page, non-product builders, you need to calculate the height of the door by deducting 8mm from the recorded opening height and enter the MAKING SIZE only.

Note: A bug seal is recommended to minimise gap at the bottom after the door is installed. This can be selected from the list of Add-ons available when calculating the price of your door.

1.1 1.2

Door Width: Measure the top, middle and bottom of your door opening/rebate(1.3), record and enter the number iinto the according text field. We recommend measuring at least twice and checking the measurements before entering into our system.

For all PRODUCT BUILDERS, if you choose the build “from scratch” option, please enter the number in the text field named opening width. The new door width will be automatically generated based on the measurement you entered.

For the fast track ordering page, non-product builders, you need to calculate the width of the door by deducting 8mm from the recorded opening width and enter the MAKING SIZE only.

If you choose to have triple locks installed for your hinge door, you need to minus 9mm from the opening width to get the exact MAKING SIZE of the door.

All the fast-track order pages require MAKING SIZE, they are calculated by you.

1.3

Hinge Bind: If your middle width is longer or shorter, creating a bow in or out at the middle, this must be corrected. For a bow in the centre, the hinge can be packed out (Hinge Packers are available on the addon page). For a bow out, the hinge will have to be let in, this must be done by chiselling the door frame to make a cutout to place the hinge.

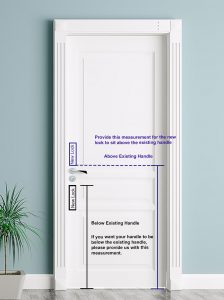

Lock Side: Stand outside, and close the main door. Establish whether you want the new lock on the left or right-hand side, then decide if you want the new lock above the existing door handle or below.

Lock Above: Measure from the bottom sill to the top of the existing solid door lock or handle.(1.4)

Lock Below: Measure from the bottom sill to the bottom of the existing solid door lock or handle.(1.4)

If you have an existing lock hole (1.6) from a previous door and you are confident that this has clearance from the existing lock, based on the Lock Above & Lock Below guidelines, then measure from the bottom floor to the centre of the lock hole. This would be the striker/ lock tongue height. You need to send us this measurement as a reply to the order confirmation email if you want us to install the lock to this measurement. We cannot guarantee a perfect fit in this situation and you may need to expand the holes still.

1.6

Lock Type:

The security sliding door will require a steel key lock for security purposes. Flyscreens can have a key lock, handle with a latch, or just handle since security is not a concern for flyscreen doors.

2. Replacing the existing door:

Door Height & Door Width: We generally recommend you to measure the size of the existing doors, if you are happy with how the door is. The new door will be exactly the same. If you are not happy about the size, you need to follow the above steps and choose to build from scratch.

Lock Height:

Lock Above: Measure from the bottom of the existing door to the bottom of the existing lock and enter the number. the new lock will be installed above this point.

Lock Below: Measure from the bottom of the existing door to the top of the existing lock and enter the number. the new lock will be installed below this point.

Lock Side:

Viewing from outside the house, identify which side the original door lock is.

Lock Type:

Security hinge doors will require a key lock, flyscreen doors can choose any type that best fits your needs.

2. Sliding Door – Measurement

TRACKS

Our security doors have top and bottom rollers. Flyscreens have bottom rollers only. Your bottom track must have a rig/guide at the centre so the rollers can run without falling off. If not, you need to purchase tracks set from us to accommodate the rollers.

METHOD

1. Measuring for a new screen door:

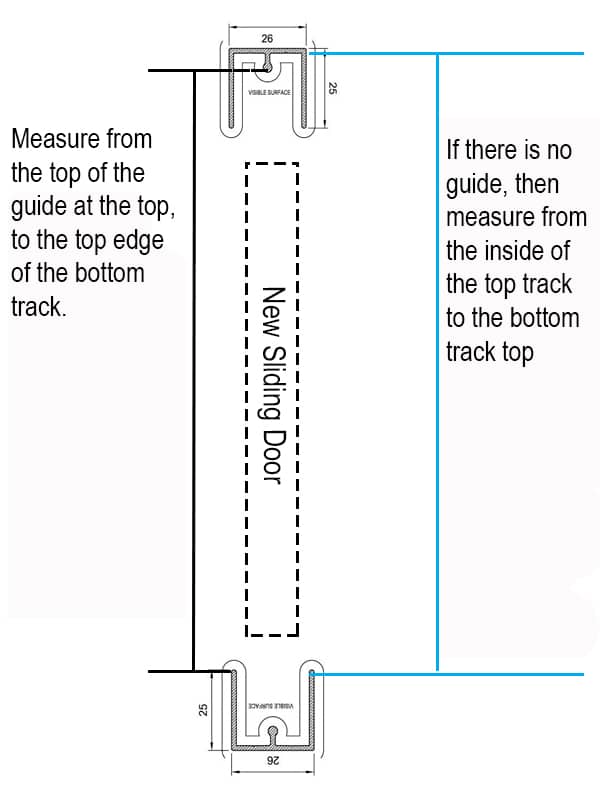

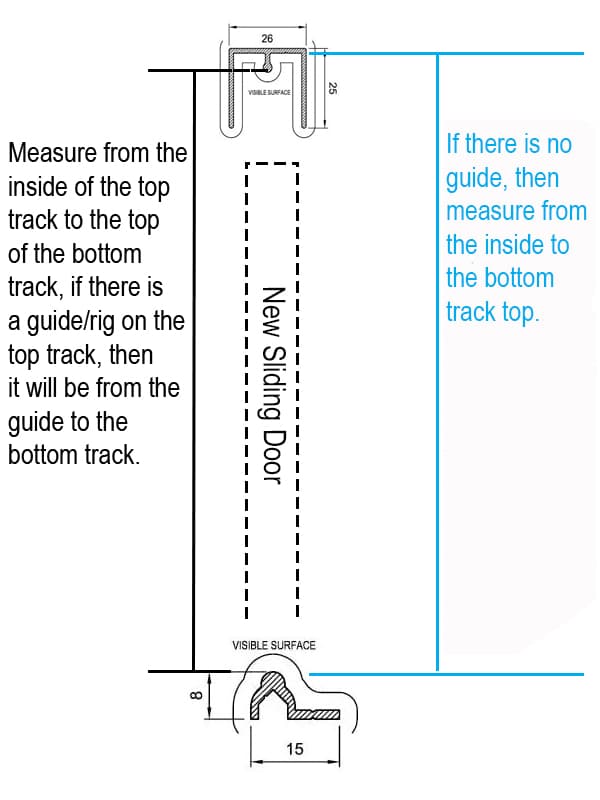

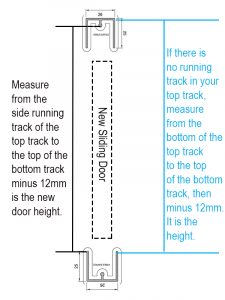

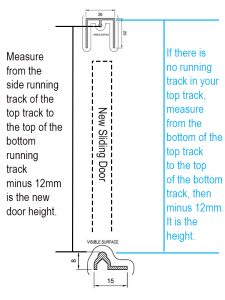

Door Height: Measure lengths at three to four points along the track; each time, take measurement from the top/inside of the top track, to the top/exterior of the bottom track.

If you are not using our PRODUCT BUILDER and are using our fast-track ordering pages, you must calculate the door’s MAKING SIZE by deducting 8mm for bottom wheels-only installation and 15mm from top and bottom wheels installation from the opening height measurement. Please only provide us with the calculated size for fabrication.

All the products listed on the PRODUCT BUILDER page will calculate the size automatically for you, you need to select “from scratch” during the build and enter the measure opening size. The page will calculate and record the making size for you.

If the product you are viewing does not have the word “BUILDER” in this product title, it is the fast-track ordering page. It is designed to order multiple products quickly and for users who ordered from us before.

There are two track systems widely adopted in Australia, one called the U shape bottom track and one called the open button track; illustrated below:

Situation 1. U shape bottom track

Situation 2. Open bottom track

After you measure the height of different locations, please check if the numbers are the same. If a variation of more than 4 mm, it means the tracks are not levelled. Some additional adjustments may be required during installation, still enter the smallest height and contact us if encounter any issues during the installation.

Door Width:

The screen door width in general is the same as the sliding glass panel width.

Single Sliding Panels:

Please measure the width of the sliding glass panel and use its width, from the edge of the aluminium frame on one side to the edge of the frame on the other side as the opening width and enter the number into the width field.

Please measure the width three times, top, middle and bottom and record the number in each field.

Stacker Doors/ Multiple Panel doors:

Please measure the width of each sliding glass panel, from the exterior edge to the other edge, and record three measurements and enter the numbers into the corresponding width fields.

Information About Interlocks

Frame Interlocks are supplied with all Sliding Security Screen Doors; flyscreen doors are supplied with a side bug seal.

The purpose of interlocks is to lock the back of the sliding door into the fixed panel simultaneously as the door is closed into the locking position, this ensures that the door is locked on both sides, see illustration below.

A frame interlock is fixed to the back of the sliding door at the point of installation so as to have it interlock with the receiving interlock which is located on the fixed glass panel.

As illustrated in the diagram above, the purpose of the interlock of the screen is to lock into the receiving interlock on the glass door. However, not all glass doors have receiving interlock installed.

No Receiving Interlock?

There are two solutions:

-

- 1. Substitute the frame interlock for a bug seal this will eliminate insects coming from through the gap between the door and fixed panel – indicate this change when placing your order, frame interlock is supplied with all Security Sliding Doors and the bug strip is supplied with all flyscreens by default.

- 2. Purchase and install a receiving interlock; refer to the instructions below.

Need to install Receiving Interlocks?

If your doors do not have receiving interlocks on the fixed glass panel and it is necessary for you to install them there are three different sizes of receiving interlocks:

- 7 mm

- 5 mm

Identifying precisely which receiving interlock is most suitable for your doors can be done using the following methods:

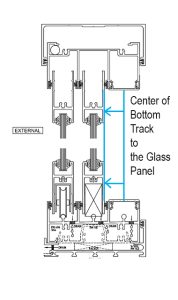

The illustration below shows where to measure.

-

If the distance from the centre of the bottom track to the face edge of the fixed glass panel is greater than 20 mm then a 7 mm offset interlock is required.

-

If the distance from the centre of the bottom track to the face edge of the fixed glass panel is less than 20 mm and greater than 16 mm then a 5 mm offset interlock is required.

Lock Height:

Lock Above: Measure from the top of the bottom track to the top of the existing sliding door lock or handle, and record the number.

Lock Below: Measure from the top of the bottom track to the bottom of the existing sliding door lock or handle, and record the number.

Lock Side:

Viewing from the outside, identify which side the glass door handle is located.

Lock Type:

The security sliding door will require a steel key lock for security purposes. Flyscreens can have a key lock, plastic latch, or handle, since security is not a concern for flyscreen doors.

2. Replacing the existing door:

Door Height & Door Width: We generally recommend you to measure the size of the existing doors, if you are happy with how the door is. The new door will be exactly the same. If you are not happy about the size, you need to follow the above steps and choose to build from scratch.

Lock Height:

Lock Above: Measure from the bottom of the existing door to the bottom of the existing lock and enter the number. the new lock will be installed above this point.

Lock Below: Measure from the bottom of the existing door to the top of the existing lock and enter the number. the new lock will be installed below this point.

Lock Side:

Viewing from outside the house, identify which side the original door lock is.

Lock Type:

Security sliding doors will require a key lock, flyscreen doors can choose any type that best fits your needs.

1. Sliding Door – Installation (Hinged Door Installation shows below)

You will need:

- Cordless Drill

- 3 mm Drill Bit

- 5/32 Drill Bit

- Phillips Screwdriver

- Hacksaw

- Pop Rivet Gun

METHOD

1. Sliding the door

When you install a sliding door it is important to align top rollers to the top track first. Then lift the bottom rollers up on to the bottom track. Slide back and forth to make sure that you have rollers correctly on the track.

With a Phillips head screwdriver adjust roller screws located on the back inside of the door. Start with the bottom rollers adjusting them only to align the door square with the closing channel. Once the door is aligned then adjust top rollers down, only enough to take up and down movement out of the door. Test this frequently as you adjust them as over adjustment may cause excessive pressure on rollers, which may damage them.

2. Installing the lock

Once the correct roller adjustment is achieved, roll the door back and forth several times to allow them to bed in correctly. From the outside position with the lock striker receiver mounted in the lock (1.2), roll door into the closed position and mark side, top, and bottom of striker receiver as it sits in the receiving channel. Remove receiver striker and line up to the marks. Drill the top hole only in the centre of elongation with a 3 mm drill bit. Now fix the striker receiver to the receiving channel and adjust accordingly. Once the lock has been tested and is functioning correctly then drill and install the bottom screw.

3. Installing the Frame Interlock

Put the door in the closed position. The back of the door should be approximately 5 mm over the fixed glass panel receiving interlock. Place the frame interlock provided on the back of the door so it fits into the fixed glass panel receiving interlock. Using a 5/32-drill bit, drill and pop rivet the frame interlock with the rivets provided. Slide back and forth to ensure correct function. In some cases it may be necessary to adjust length the of frame interlock, this can be done with a hacksaw.

4. Fitting the Bug Seal (If required in place of frame interlock)

Put the door in the closed position. The back of the door should be approximately 5 mm over the fixed glass panel. Place bug seal with brush hair facing the glass on the fixed glass panel. Make sure that you centre the seal so it misses top and bottom tracks. Drill and fix with 3 mm drill bit and pop rivets provided.

2. Hinged Door – Installation

Please view all our guides provided before proceeding with your installation

- You will need:

- 10 mm Chisel

- Hammer

- Cordless Drill

- Phillips Driver Bit

- 3 mm Drill Bit (1/8 imperial)

- Pencil

Note: If you require a bottom bug seal, it should be installed last.

IMPORTANT: When assembling and installing your lock the snib (the silver lever used to lock and unlock the door without the key) must be in the 12 o’clock position – if this is not installed correctly to your locking mechanisms will not perform correctly.

1. Swinging the door

Hold the door in the open position 4-6 mm down from the top of jamb with hinge open and resting against the jamb, mark the centre of the elongated hole in the top hinge (1.1).

1.1

1.1

1.2

1.2

1.3

1.3

Using a 3 mm drill bit, slightly pre drill a pilot hole on the mark you have just made (1.2).

Hold the door in place and using a cordless gun, screw through the centre elongated hole into pilot hole and screw up tight (1.3). Repeat the same process using the centre hole of the bottom hinge. Now close the door onto the jamb and stand outside. Adjustments up and down can be made now if necessary by loosening the two screws. Once you are happy with the doors position then pilot drill and fix all remaining screws to the hinges.

2. Fixing the lock

Whilst holding the door in the open position, push the round trigger on the main lock to extend the tongue into the locking position.

Close the door up to the jamb and mark above and below the tongue (1.4).

1.4

Now open the door and use the striker plate as a guide to trace the two holes and the rectangle tongue hole onto the jamb, using the marks as a guide. (1.5)

IMPORTANT: The round trigger is not designed to go into the main tongue hole. It is a designed to trigger the main tongue only and must not go in main tongue hole. It is designed to slide just above the hole and stay in the depressed position on the main striker face.

1.5

1.5

Using a 3 mm drill bit, pilot drill the two screw holes. Then ribbon drill the complete outer area of the tongue hole. (1.6)

1.6 1.7

Using a 10 mm wood chisel and hammer, extract timber to make the hole needed for the main tongue (1.7). Make sure that this hole is cleaned out completely and that no tongue restriction remains.

Fix the main striker plate into position with the two screws provided. Complete the Simple Lock Check to ensure the door is now locking in both open and closed positions with exactly the same non restricted action, deadlocking the internal snib when locked with the key.

3. Simple Lock Check

Use the following method to ensure lock is operating correctly:

- Open the door, pull down on the handles and release.

- Without touching the door handles, depress the small round trigger above the main tongue, this will allow the main tongue to fully extend, this is the correct lock check position for your lock.

- Without touching the door handles, use the internal snib to engage the lock. In the case of 3-point locks the top and bottom strikers will also extend. Do this several times to gain the appropriate feel of how the lock should correctly engage without restriction.

- Close the door and without touching the handles repeat the process. If you do not feel the identical sensation of the lock then you have a restriction.

- If you have a restriction you must inspect the lock holes to find and then clear the obstruction, test and retest until the door locks with the same feel both open and closed.

4. Point Lock: For 3-Point Lock

Whilst holding the door in open position push the round trigger on the main lock so the tongue extends into the locking position. Using the key, lock the door, all three tongues will be in the exposed lock position. (PLEASE NOTE: The two vertical strikers; one from the underside of the bottom tongue and the other from the upper side of the top tongue).

Close the door up to the jamb and mark above and below all three tongues including the vertical strikers on top and bottom tongues.

1.8 1.9

Now open the door and use the striker plates as a guide to trace the two holes and the rectangle tongue hole onto the jamb using the marks as a guide for all three tongues (1.8). Make sure you give clearance for the two vertical strikers.

Using a 3 mm drill bit, pilot drill the two screw holes on all three-striker plates. Then ribbon drill the complete outer area of the tongue holes. (1.9) Using a 10 mm wood chisel and hammer, extract timber to make the holes needed for main tongue and top and bottom tongues. Make sure that all holes are cleaned out completely, and that no tongue restriction remains.

Now fix main striker plate into position as well as the top and bottom plates with the screws provided (1.10). Re-check the door is now locking in both open and closed positions with the same non-restricted action, also check that it is deadlocking the internal snib when locked with the key.

1.10

Close the door and using the key lock the door. If the lock hole has no restriction then it should lock effortlessly. Now go inside and repeat this process. This action should deadlock the internal snib, if it does not then there must be a restriction and it will have to be removed.

5. Installing bug seal

The installation of a bug seal is done after the door is installed to ensure a perfect fit. Remove the adhesive tape and apply it to the bottom of your door. For added strength fix with pop rivets or screws.

Allow the seal to rest on the bottom of the door resting on the sill. Do not push down. Using a 3 mm drill bit (1/8 imperial) drill a hole through the top section of the bug seal (1.12) and directly into the bottom of the door. Pop rivet and repeat at the opposite end (1.13).

1.12

1.12 1.13

1.13

Sliding Door – FAQ (Hinged Door FAQ shows below)

- What are the recommended measuring deductions for Sliding Doors?

A. We can only advise the standard allowances. Some doors may have individual quirks. Please provide measurements in millimetres. The measurements you provide will be the exact measurements your door will be fabricated. Please check your tape for accuracy. Measure your door from the outside looking in.

There are two types of bottom tracks that you need to consider. Please view the diagrams below, indicating how to measure in each situation.

Situation 1. U Shape Bottom Track

Situation 2. None U Shape

Standard drop deductions – 12 mm.

Standard width deduction: Take no deductions. You can measure the existing glass door width and use it as the width of the sliding screen.

- What are interlocks?

A. The purpose of interlocks is to lock the back of the sliding door into the fixed panel simultaneously as the door is closed into the locking position, this ensures that the door is locked on both sides. A frame interlock is fixed to the back of the sliding door at the point of installation to have it interlock with the receiving interlockwhich is located on the fixed glass panel.

There are three different sized receiving interlocks:

- 3 mm offset interlock

- 7 mm offset interlock

- Flat interlock

3 mm offset interlock: When measuring for widths with 3 mm offset interlock allow no deductions.

7 mm offset interlock: When measuring for widths with 7 mm offset interlock allow no deductions.

Flat interlock: When measuring for a flat interlock add 10mm to your initial door width measurement. The reason for this is to have the frame interlock that is to be located on the back of the door to have. The nature of flat interlock does not allow enough room for the frame interlock to go between itself and the fixed glass panel, therefore adding 10 mm will allow the frame interlock to locate behind the fixed glass panel to allow room.

- What if my door does not have a receiving interlock.

Substitute the frame interlock for a bug seal this will eliminate insects coming from the through the gap between the door and fixed panel – indicate this change when placing your order, frame interlock is supplied with all Security Sliding Doors.

Alternatively a Receiving Interlocks can be purchased from ScreenWarehouse; contact the office for assistance 02 8385 4553.

- Why do you need a lock height?

A. To manufacture your door with the lock away from your existing handle for both sliding and hinged doors. So, they don’t bump each other. - How far above or below our existing solid door handle do we put our required lock height?

A. Please kindly check the photo illustration provided in the product ordering section above. We generally prefer to have the next lock either above or below the existing lock to avoid any chance of interference. - Do you have a showroom that I can visit?

A. Yes. You can visit our contact us page for opening hours and address. - What Powder Coat colours do you use?

A. Colours are standard Dulux Powder Coat colours. - Can I have another Colour if I am willing to pay for it?

A. Yes. Prices will have to be individually quoted. Please email [email protected] - Do you do Security Grilles?

A. Yes, we sell 316 Marine Grade Stainless Steel mesh security grilles. - How does your door compare with other similar doors?

A. We offer no comparisons to any other similar products. Our doors are as described. We stand by our quality, service and warranties as described. - How long does it take?

A. The door is manufactured within 2 working days from receiving your measurements. Once goods are dispatched you will be sent a dispatch notification. - Can I pick the door up?

A. If you live locally yes, otherwise we ship Australia wide. - Do you discount for multiple doors?

A. No, however we can discount freight for multiple items. - Can multiple doors be made keyed alike?

A. Yes, in lots of ten. - Can the door be made out of square?

- No.

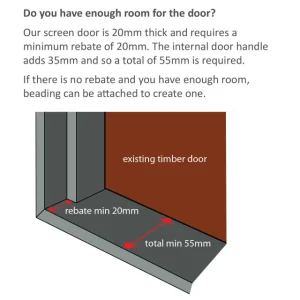

- What is the thickness of the door frame?

- Standard 20mm

Hinged Door FAQ

- What is a Triple Lock Upgrade?

- A Triple Lock Upgrade is a locking system that is activated from the locking handle position and has 2 additional strikers.

- Do SWH make deductions for hinged doors?

- No. The measurements you provide will be the exact size fabricated.

- What deductions do I make?

- We can only advise as to the standard allowances. Some doors may have individual quirks. Please provide measurements in millimetres. The measurements you provide will be the exact measurements your door will be fabricated.Please check your tape for accuracy.

- Standard width deductions: 9 millimetres off all three widths for three-point locks and 8 millimetres off for single locks.

- Standard drop deduction: 8 millimetres off the shortest length. We keep both lengths the same to ensure door can be made square; a small gap may appear at the bottom of the door. This can be eliminated by installing a bug seal which can be purchased from our accessories section.

- Take your lock measurement from the bottom [ground] to the centre of where you want your lock handle. This will also be the centre of middle lock striker. This measurement needs to be a minimum of 120 millimetres above your existing door lock or 60 millimetres below.

- What if I have an existing door and it is a perfect fit?

- If you are happy with size of the door you have, this is a good idea.

- Why do I measure from outside looking in?

- To determine which side for both lock and hinges.

- Can you offer any suggestions to help gain accuracy with measurements?

- Yes. Measure multiple times and perhaps have someone else measure as well. Remember we will supply the door to the exact measurements you provide.

- What if my door is out of square?

- We can make the door off square in the range of 0-5mm without showing a significant at the joint. Any variation larger than 5mm in width or height differences will result in a minimal 3mm gap at the joint. It is standard practice to pack the hinges rather than making an off square door to accommodate the opening. With that being said, we can do the door off square with an extra charge.

- Does the door come with a door closer and bug seal?

- No, they can be purchased as an add on.

- Do you install?

- Yes, we provide installation and measurement, you can find the service on our website at ‘Services’ in the home page menu. You can also find intallation method in the DIY center for intalling by yourself.

- Does the door come with a door jamb?

- No.

- Does the door come with screws to fit?

- Yes for timber fit only – Hinged doors only.

- Why do you need a centre of the door lock height?

- To manufacture your door with the lock away from your existing handle for both sliding and hinged doors. So, they don’t bump each other.

- Is the centre of the handle the centre of the main tongue?

- Yes.

- Can I match an existing tongue hole?

- Yes. If you have an existing tongue hole and it has not interfered with the main solid door handle, then this can be re used. Measure from the bottom up to the centre of the hole and deduct 4 mm.

- How far above or below our existing solid door handle do we put our required handle height?

- Below: Measure from the ground to the bottom of the existing solid door lock. View photo illustration in the order section.

Above: Measure from the ground to the top of the existing solid door handle. View photo illustration in the order section.

- Does the internal snib lock the three-point lock?

- Yes.

- Do I need to recess the hinges?

- No. However if there is a bow in the hinge side jamb, then recessing or packing the middle hinge may be necessary.

- If I have a current door that I am replacing, and it has the hinges that have been recessed. What do I do?

- You can either have the hinges replaced to avoid the recesses and repair the existing recesses or have them placed exactly where they exist now.

Note: If you have them placed where they exist now it will affect the width deductions. We would only recommend this if you were measuring an existing door that you are happy with the fit.

Shipping

Once your order is custom-made to your specifications, it is then packaged for shipment directly to the shipping address. Once dispatched, you will be sent a tracking number.

From the time you place the order, your item will be dispatched from our workshop within 5-7 business days. Any delays in delivery will be communicated to you by our staff.

Delivery Time Frame

| Destination | Time Frame |

| Sydney, Melbourn, Brisbane Metro Area | 1-3 Business Days |

| Regional NSW VIC | 5-10 Business Days |

| Regional QLD | 7-15 Business Days |

Extra Fees

For delivery to rural areas, we may ask you to pay some extra fees to cover the additional charges by the specific courier to your areas. We book our deliveries from transidrect.com.au. If you receive such an email requesting additional payment, you can check the website with the shipment details to review the shipping costs.

Our shipping fees are competitive if you are located in metro areas in Australia. However, some rural areas only have a very limited number of couriers and they charge significantly higher than our standard rates.

Alternatively, we can refund you the shipping fees, and you can organize the delivery from your end. We will disclose the shipment information in the email seeking extra fees. You can reply to us if we wish to do so.

Lastly, we can also refund you in full if you do not wish to proceed with the order, due to the extra fees.

For flyscreen products, we also offer flatpacks in a box, Check our flatpack windows, and flatpack doors, which we offer as free shipping items.

If you encounter any issues or have any questions during the ordering process please phone us on 02 8385 4553, we are always happy to help.

* Pending availability of stock (SWH will advise of any stock shortages that may extend the manufacturing time).

Return Policy

Please note all of our products are custom ordered and fabricated. We do not accept returns for refunds if:

- you change your mind, not wanting it anymore;

- you want a different colour or a different product;

- the product does not fit the opening, is too big or too small;

- there are scratches on the products upon delivery;

- the mesh on the screen is not tight enough;

There are situations, where the products may be scratched. In this situation, we will need you to provide us with photos of the products received within 3 business days of delivery and show us the scratches. Unless the scratches show cuts into the materials resulting in the materials bent or breaking apart, generally they are not enough to warrant a refund.

According to AS/NZS 2803 Doors Security Screen, the primary purpose of a screen door is to create a safety barrier between the household and the intruder that can survive and withstand a certain level of impact. We generally do not consider scratches to be defects, but we do our best trying to avoid them by packing the products with layers of cardboard before delivery. We also generally leave the protective film intact when fabricating the doors. However, it does not guarantee the products will not have minor scratches upon its delivery. Please take this into account before making a purchase.

When fitting a metal mesh onto the flyscreens, it is impossible to stretch the mesh tightly, because 1. the mesh is harder than the aluminium frame; 2. the frame is not strong enough to hold the pressure of the over-stretched mesh. We generally do not recommend stretching the mesh very tight, regardless it is a metal or nylon mesh. A stretched mesh can break more easily under pressure or weather.

We will stretch the mesh to the degree that it will not cause the frame to deform and not break easily. If you find the mesh not stretched to the level of your old mesh or to your liking, there is nothing we can do because the materials that we used could be very different to what you had. Please consider the fact that the screen is to stop flies and insects, not anything else.

We will issue a refund if:

1) the product is deemed lost or stolen in transit; depending on the investigation of the courier company;

2) the product is significantly damaged, bent, or no longer fits its purpose upon receipt, you must contact us within 3 days of its delivery;

3) the product is fabricated significantly differently from the size requirements that you sent us; in this case, the difference must be greater than 5 mm and renders the product unfit for its intended purpose.

Please note that all the products are hand made and the tape measure can have a loose or tight fitting at the endpoint. Because of these reasons, a difference in tape reading of 1~4 mm should be considered within the margin of error and there are remedies that we can offer to fit the products without making any significant changes. We will not issue refunds or accept any returns in this case.

Related products

Door Product

One-Way Security Mesh

Security One-Way Mesh Door Hinged/Sliding Custom Size Available

Diamond Grille

Security Doors